My hoop is not round!

1. Almost no extruded hoop is ever perfectly round as by nature they have to have a join. As the join will not curve the same as the rest of the hoop and will cause some stress on the overall shape.

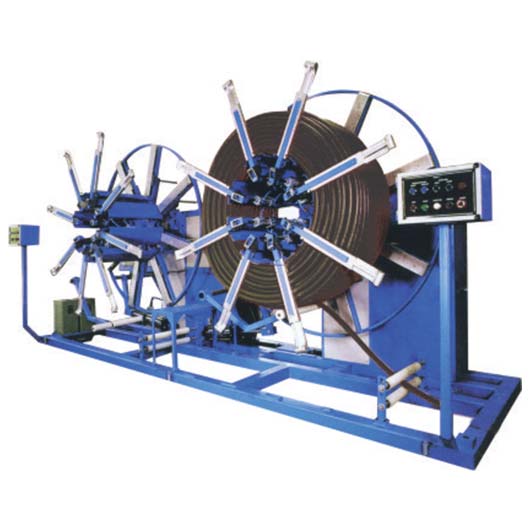

2. As the pipe comes out off the extruding process (moulding) it gets set into a coil at varying diameters as the coil grows in size (See image above). As it cools it sets into a less stressed natural curve. Making a hoop in different diameters will always have stresses fighting against one another to get back to it’s natural formed shape. This becomes more apparent with a greater difference between extruded coil size and the finished hoop and therefore greater the stress on shape and at the join.

3. Shipping a single full sized hula hoop is extremely expensive due to it being charged at a size/volumetric rate (not by weight). So we have to make our hoops into double coils or breakdown/sectional for the shipping process. Alas this method does take a bit of time to naturally correct itself once unpacked. However this can be corrected faster using the tips below.

Ideally raw uncut coils of extruded pipe should be as close to the diameter of finished hoops to minimise the stresses which can result in irregular (under or over) bending.

Remember it does not need to be a perfect round shape to work as a hula hoop, however when doing certain moves like "Isolations" we understand the requirement of it being more circular for the illusion.

Tips to make your Hoop "Rounder"

- Use it. Yes this will help to destress the hoops natural bends.

- Store the Hoop Flat, eg. under the bed.

- Store sectional (multi-part) hoops joined together as a hoop. Dismantle for travel only.

- Guide it by placing heavy items beside (inside, outside, underneath and/or on top ) the hoop to curve the "straight parts" and to "straighten" the overly curved parts. Slightly over and under bending will help you get there faster.